di Luciano Falqui e Alessandra Evangelista*

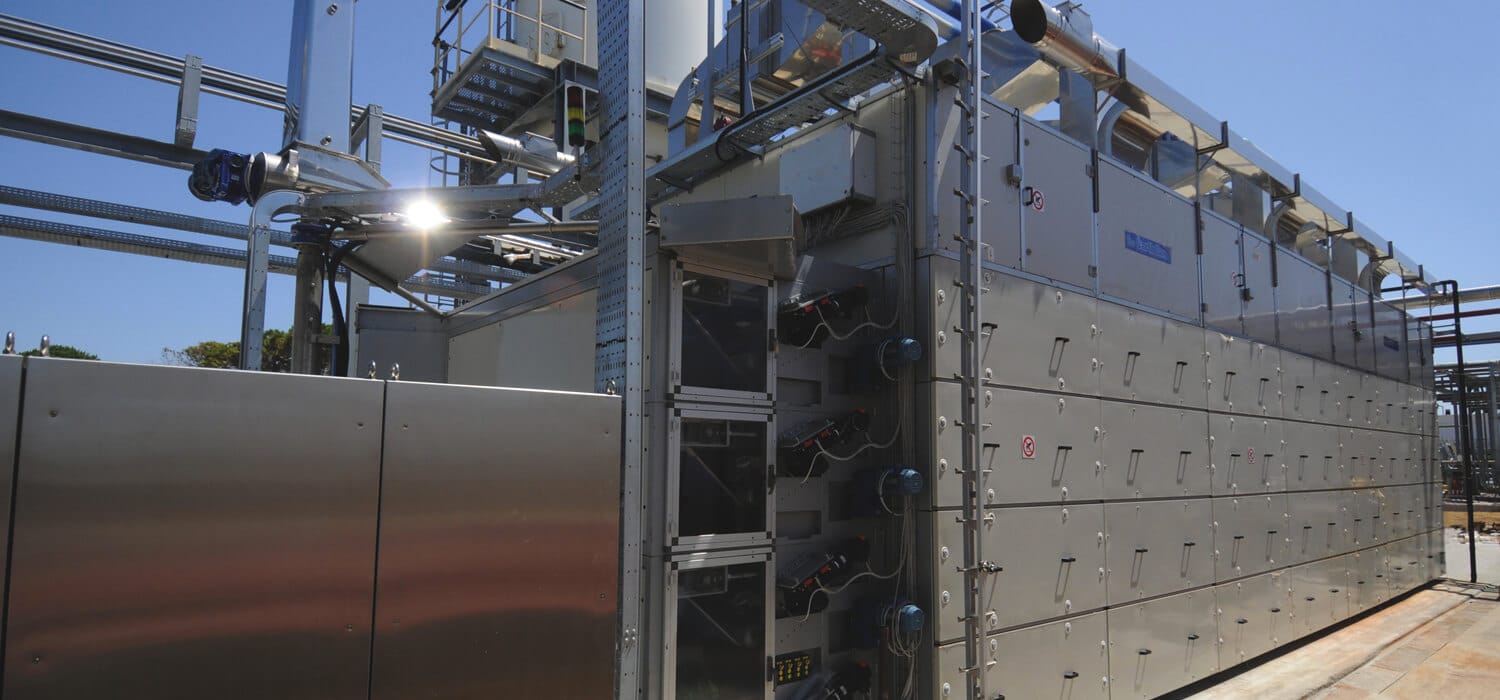

The research and development department of Officine di Cartigliano, beside from continuously working to improve its tanning machinery, has also enlarged its reach to touch on the environmental segment as well, because it is a sector that is becoming increasingly strategic. Specifically, the department developed a low temperature drying system able to dehydrate the waste water that is produced during the tanning process. Even when starting waste products with humidity above 85%, the system (created by Officine di Cartigliano), manages, while working at low temperatures (70 degrees Celsius) and saving energy, to remove humidity and causing the waste to have less than 10% humidity. This system allows chromium-filled waste to also be worked in complete safety. With the goal to drastically reduce the waste’s volume, and if there is a heating power that is powerful enough, a molecular dissociation system has been created, which works between 550 and 700 degrees. This system works with complete lack of oxygen, and is able to convert the organic matrix present in the waste products into a carbonized sub-product (CHAR) and a gas that can be used to produce energy. Under an environmental point of view, the process takes place with complete control over the emissions released, and makes it possible to concentrate all the metals into the physical residue. More in depth, the specificities of the process are able to keep chromium in a trivalent state. The synergy of these two processes (drying + molecular dissociation) allows for strategic projects to be developed in the environmental field within the tanning segment.

* Luciano Falqui is an industrial chemist specialized in bio-molecular valorisation and organic matrixes’ energy capabilities, reached via advanced thermochemical processes. Alessandra Evangelista, graduate with a degree in Environmental Engineering, is part of the R&D segment of Officine di Cartigliano, and is involved in the development of drying systems and other new technologies that deal with the treatment of industrial waste. Officine di Cartigliano has been developing and creating machinery for the tanning of leather for over 50 years. The business ceo is Antonio Polato, who focuses his constant attention “to the development of machines that allow for high standards of quality”, something that has made the company leader at a global level.