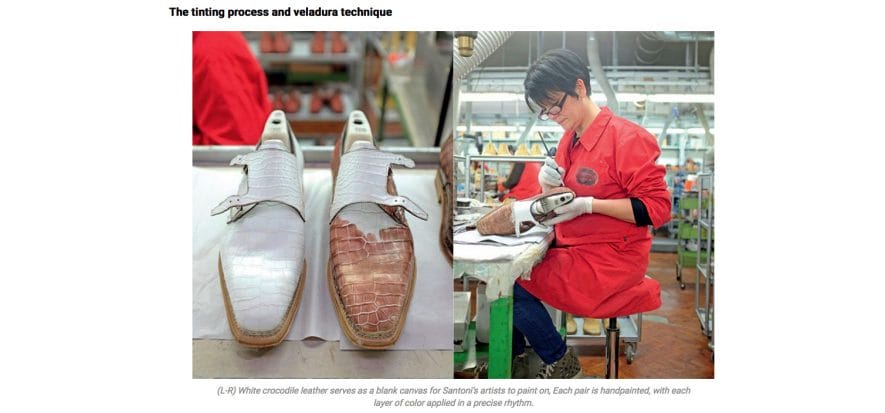

First, they check leather; then, they cut and sew it, and subsequently assemble footwear spare parts. Ultimately, they make it finished. Journalist David Celdran, from ANC portal, took some pictures and wrote down a few short descriptions of the multiple processing stages at Calzaturificio Santoni (Santoni shoe factory). After visiting their manufacturing laboratory based in Corridonia, in the province of Macerata, he gave a fully detailed report over the long and meticulous work process carried out by the manufacturer to make shoes. You can read it by clicking here. The company tour began in the warehouse, where they keep the valuable leather Santoni’s shoes are made of: such leather is “a naturally elastic material, therefore footwear artisans can easily process it”, remarked Celdran. Subsequently, some wise and specialized artisans start processing the leather samples, which are all different: they treat and cut raw material very meticulously. “In most shoe factories, all over the world, in Italy as well, machinery have replaced workers during the assembly stage”, pointed out the journalist. Conversely, at Santoni artisans are the ones who are still up to components assembly”. At that point, you can make out the shoe’s three-dimensional shape; they bring the process to completion by gluing the components of sole. Ultimately, and this is one of the most important stages, they carry out their unique “glazing”: “In fact, Santoni’s art experts apply 4 to 15 layers of tint to create an amazing effect on leather. Blank leather is like a canvas, and each tint, among thousands developed by Santoni since 1978, comes from a secret formula”.

A picture screenshot from the news report