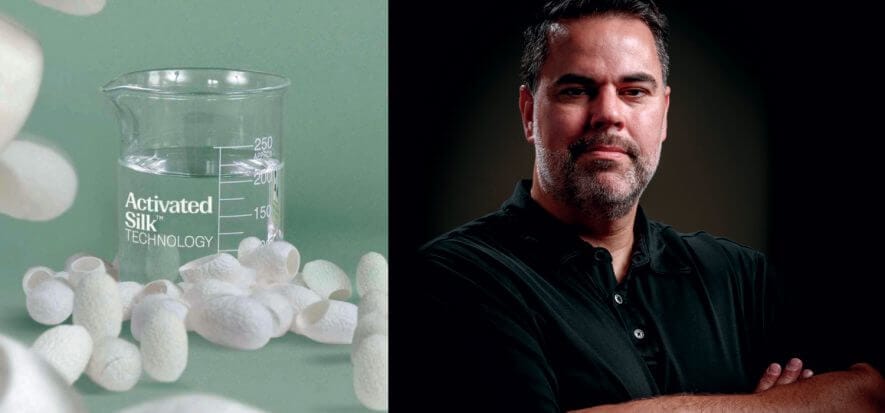

Greg Altman (in photo) is the CEO of Evolved By Nature, US-based biotech company that he founded with Rebecca Lacouture. The enterprise is a player in the “green chemistry” segment and entered the market with Activated Silk, a technology capable of allowing the extraction of proteins from silk. These proteins can be used for a variety of activities, including the making of sustainable finishing for leather. We spoke with Altman about his projects and objectives.

When and why was Evolved By Nature™ created and how is it organized?

Evolved By Nature is biotechnology company founded in 2013 in Boston, Massachusetts by myself and Dr. Rebecca Lacouture. We hold PhD’s from Tufts University – me in biotechnology engineering and Rebecca in biomedical engineering. Today, the company is a diverse group of scientists, researchers, leather and textile experts, and creative professionals, all drawn together to help create a healthier, more sustainable future.

Why was Evolved By Nature founded? The short is answer is: Because humans need a better way of taking what we need from the planet. We can no longer depend on fossil fuel derived petrochemicals or ingredients produced using unsustainable processes to make products possible. We use proprietary technology to discover and unlock powerful molecules from natural, renewable resources in a way that is supportive of nature’s positivity and circularity. And we in turn use those molecules to facilitate the next generation of products that will advance the health of people and the planet.

Our current sustainable molecule platform – Activated Silk™ biotechnology – is bioharvested and designed from silk protein. Activated Silk™ molecules are currently in various stages of product development and commercialization in three markets: sustainable chemicals for textiles and leather, natural ingredients for cosmetics and agriculture, and biomolecules for regenerative medicine. Sustainable Activated Silk™ chemicals are sold directly to tanneries, with our R&D division actively creating new biobased formulations. Our ttechnicians in the United States, Europe and Asia are available to assist in article development.

What are the applications and, in general, the sustainable benefits of Activated Silk™ technology?

Activated Silk™biotechnology exists in a rare class of molecules. The production process is sustainable, supportive of circularity, and achieved with good work practices. The silk molecules themselves serve as an alternative to many environmentally harmful chemicals and polymers and they’re biodegradable, making them completely compatible with the planet’s ecology.

By replacing harmful ingredients applied to natural substrates (i.e., ingredients that are environmentally harmful to produce and harmfully persistent in the environment), Activated Silk™ biotechnology is one of the final keys for making biodegradable, compostable, and recyclable natural leather possible. It also supports the human health aspects of sustainability goals by mitigating harmful chemicals where leather is processed and manufactured, reducing human exposure to environmental pollutants.

Tanneries are already using Activated Silk™ biotechnology in the finishing process. Different formulations offer different benefits, including:

- Replacement of synthetic chemicals such as polyurethane. Tannery partner, “we reduced polyurethane across the entire finish by 30%.”

- Colorfastness to rubbing for full grain leather: Tannery partner, “One of the last steps needed to make a fully biodegradable and compostable aniline leather was improving colorfastness to rubbing, and Activated Silk™ technology was key.”

- Reduced bleeding in nubuck as indicated by colorfastness to PVC migration. Tannery partner, “this reduces pre-consumer waste, as well as customer returns. I was shocked, the results were so impressive.”

- Good plate release: Tannery partner, “Activated silk chemistry worked better than our standard intermediate coat, preventing the leather from sticking to the printing plate.”

How is the Activated Silk technology supply chain organized?

Farming: mulberry trees are grown using organic methods – no pesticides or synthetic fertilizers, and irrigated by rain water. The mulberry is cultivated in a way that allows the same trees to thrive season to season, keeping the soil healthy and stable. A portion of leaves are harvested seasonally and fed to silkworms, who in turn spin silk cocoons.

Harvesting: cocoons are then harvested. The silkworm pupae are extracted in an ethical and cruelty-free process while in a state of stasis during which their transitional physiology allows for zero stress or pain. The pupae are used to support a natural food chain, and the biowaste – the cocoons – are shipped to Evolved by Nature in recyclable containers. We are always exploring and vetting potential silk suppliers closer to our manufacturing locations to mitigate shipping energy.

Activated Silk™ biotechnology: through our proprietary process using only water, salt, renewable energy and science, the two components of silk – fibroin and sericin – are seperated. The sericin and salt are extracted, leaving only the fibroin which is liquified and filtered so that we can bioharvest pure, natural silk protein molecules that become Activated Silk™ biotechnology. Molecules are designed to meet specific performance needs, and then used to create sustainable chemical formulations.

Shipping: products will be shipped to a 3PL in Europe and Asia in Q4 2021, and from there will be shipped to our tannery partners. As we continue to grow, we will build manufacturing facilities near key clients, and to reduce carbon emissions and shipping costs associated with liquid formulations, we will have Activated Silk™ tablets available in 2022.

How is the Activated Silk technology supply chain sustainable?

We use the United Nations Sustainable Development Goals (UNSDG) as a framework for sustainability assessment. Activated Silk™ biotechnology is an environmentally responsible technology developed with good work practices, which contributes to:

- UNSDG 3: Good health and well-being

- UNSDG 5: Gender Equality

- UNSDG 6: Clean water and sanitiation

- UNSDG 8: Decent work and economic growth

- UNSDG 9: Industry, innovation and infrastructure

- UNSDG 12: Responsible consumption and production

- UNSDG 13: Climate action

- UNSDG 14: Life below water

A third-party lifecycle analysis has been completed for the supply chain as well, to determine the carbon emissions from the complete process. Compared to publicly available data for synthetic chemicals, the process of creating Activated Silk™ biotechnology has a smaller negative impact on the environment. Activated Silk™ biotechnology is also non-toxic, non-GMO, biodegradable, all-natural and biocompatible.

How is Activated Silk™ technology applied to the leather?

Activated Silk™ technology is easy-to-use, with application like other finishing agents, via spray or roller coater.

Can Activated Silk be used on all types of leather? To what extent does it enhance its quality and performance, as well as its sustainability?

Activated Silk™ biotechnology is extremely versatile and can be used as a sustainable finishing agent for all types of natural leather as well as composites and new innovations in circular and sustainably created substrates. Activated Silk™ biotechnology enhances the sustainability of leather because it can be used in lieu of synthetic chemicals that more often than not release toxicants into our environment, have unknown end-of-life consequences on our soil, water and air, and in many cases prevent the leather’s biodegradebility, compostability or recyclability.

In terms of performance, silk molecules are amazing monomers-polymer with incredible performance properties that many of today’s synthetic polymers have been designing after. And performance and sustainability further overlap in abilities such as colorfastness to PVC migration, which further benefits the environment since it helps reduce waste in manufacturing.

What business goals do you have?

We’re in the business of advancing human health and helping the planet. There are business goals that fall under that, like becoming the best sustainable chemistry company with the best technical support team in the industry. And reducing market share of fossil fuel derived chemicals in the leather industry. And building a movement around the idea that neither petrochemistry nor synthetic biology will solve the climate crisis and the toxification of the biosphere. But at a high level, there will be no business without human health and environmental sustainability. So ultimately, positively impacting them is the goal.

Read also:

- At Boston Innovation Training MIT lectures: “Leather to be smart, it has no limits”

- Boston Innovation Training, how to build an innovative ecosystem

- At Boston Innovation Training, they gear up to contaminate the future. Crazy? Not really